Custom-Built Safety Tools for Real-World Challenges

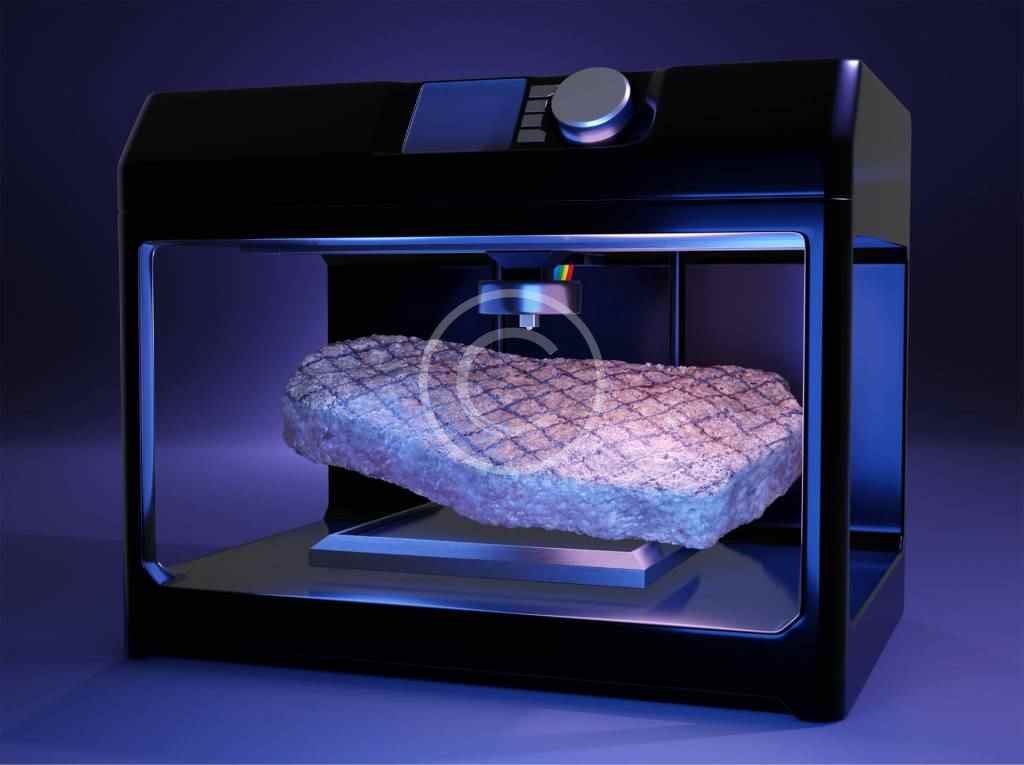

3D printing empowers the creation of custom safety tools and equipment designed for specific environments and use-cases. Whether for protective gear, ergonomic tools, or safety enhancements, 3D printing enables rapid development, low-volume manufacturing, and precision adjustments. Ideal for industries requiring adaptable and compliant safety solutions without the delays or costs of traditional production.

Empowering Safety with Precision 3D Printing

-

Customized Safety Solutions – Tailor tools to specific operational or environmental needs.

-

Rapid Production – Create and iterate safety components quickly.

-

Ergonomic Designs – Improve comfort and reduce fatigue with user-specific features.

-

Cost-Effective Manufacturing – Ideal for small-batch or one-off safety gear.

-

Durable Materials – Choose high-strength materials suited for rugged use.

-

Prototype to Production – Test and validate tools before full-scale deployment.

-

Compliance-Friendly – Modify designs to meet industry safety standards efficiently.